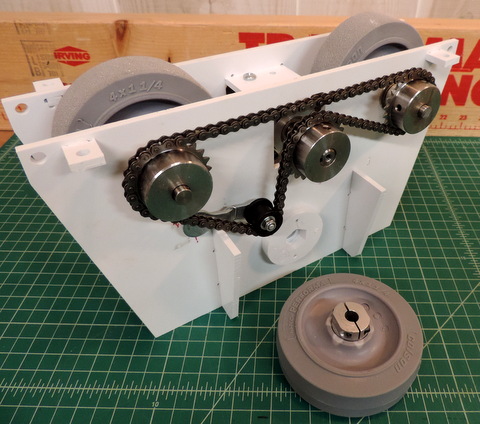

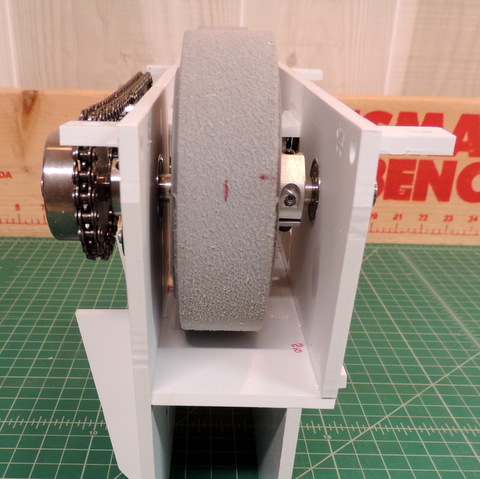

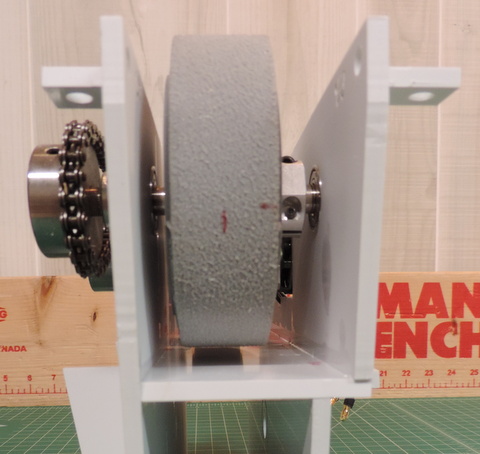

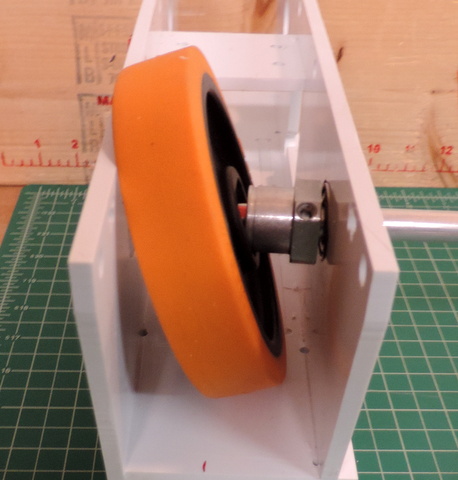

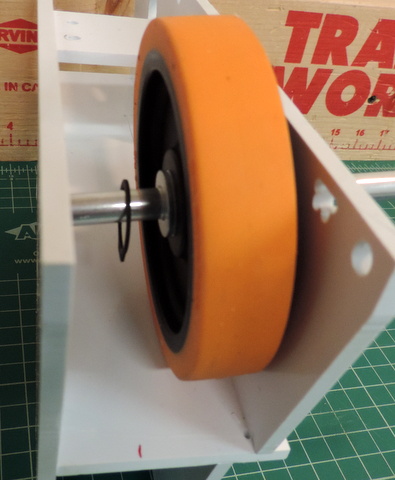

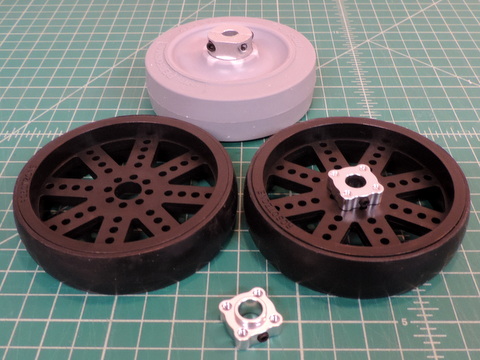

This was the foot drive design. It utilized a 4 in x 1.25 in Colson wheel

with a pressed in clamp hub offered by BaneBots.

This was the foot drive design. It utilized a 4 in x 1.25 in Colson wheel

with a pressed in clamp hub offered by BaneBots. Banebots also offered it ground down so it had a flat surface.

Note that that reduces it's OD from 4 in to 3 7/8 in.

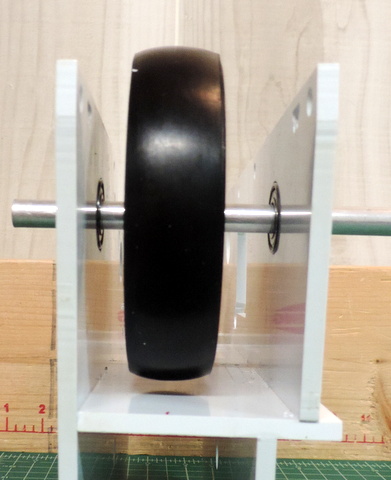

1. Two driven wheels of the same size.

2. Wheel contact surface flat enough for good traction.

3. Wheel centerline to be lined up with Leg centerline.

4. Components used 'off the shelf' with no, or very minor modifications required to be made by the builder.

I was really excited when I discovered the BaneBots wheels since that eliminated a major stumbling block to using the Colson Wheels. In my R2 foot drive, the sprocket gear has to be attached to the wheel by the builder after having it's bore enlarged to accomodate the 1/2 in shaft. That also required drilling mounting holes in the sprocket and into the wheel.

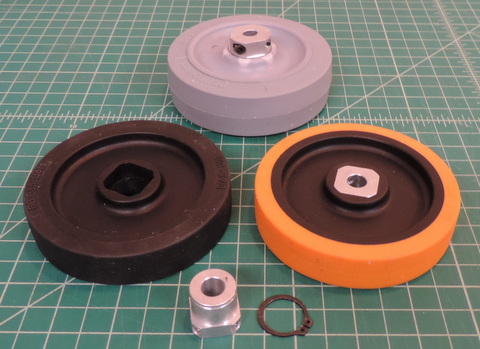

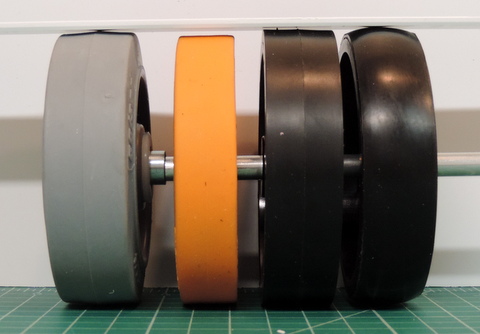

You can imagine my disapointment when BaneBots decided to discontinue their Colson product line. I conducted a rather exhaustive search for compatible 4in wheels that could be used in place of the BaneBots/Colson parts. There are not all that many acceptable products that would match the 4 in, x 1.25 in profile.

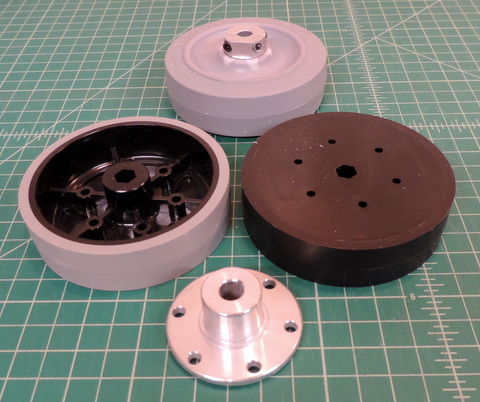

One that I initially skipped over was the Banebot's T81 line of wheels. These are apparently what they consider the replacement to the Colson wheels even though they are considerably narrower (.8 wide). The hub has a setscrew to hold it to the shaft, then the wheel is held to the hub with a snap ring. On evaluation, assembling the wheel to the hub is going to be difficult in the limited space available.

You have to tighten the setscrew before the wheel in in place.

and then install the snap ring. That step requires a snap ring tool.

I also evaluated wheels from AndyMark. I was attracted to these 4 in. wheels because they were 1 in. wide. The wheels are intended to be driven by a hex shaft. I managed to overlook the problem of the size of the drive hub I would need to adapt them to a round shaft!

There's simply no space. Adapting the wheel to use a different hub would be possible, but would violate the 4th design constraint.

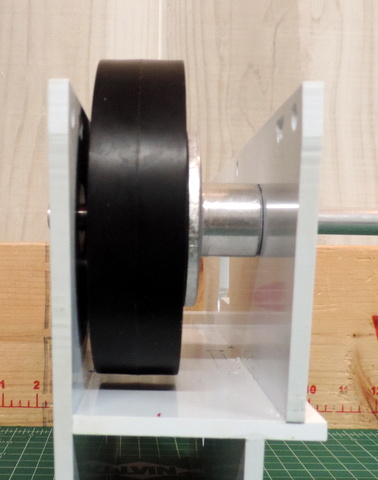

While I initially looked on ServoCity (Robotzone/Actobotics) web site I managed to miss their 4 in. Heavy Duty wheel. It's profile at 4 in x 1 in. almost matches the original Colson 4 in x 1.25 in profile. They sell a set screw hub that bolts into the wheel. If you are not happy with the amount of contact surface between the hub and the shaft (the hub is only .375 wide supporting a 1 in wheel slightly off center). you can mount a second hub on the other side.

At this point I've decided to go with the ServoCity Wheels. They can easily be put in place of the Colson Wheels without making design changes to the other parts of the design.

4" Heavy Duty Wheel

https://www.servocity.com/4-heavy-duty-wheel

part #595410

0.770" Pattern Set Screw Hubs

https://www.servocity.com/770-set-screw-hubs

.375 Bore part #545556