Vacuum Hold Down

First Pass

This is my first pass at laying out a vacuum hold down table. I based my design on a number of web sources.

DIY Vacuum Table posted in the CNC for RC Forum.

The CNC Zone - work fixtures and hold down solutions forum.

Vacuum Table - link from a posting by Gaston Gagnon on the Fireball CNC Forum.

You can download an autocad drawing.

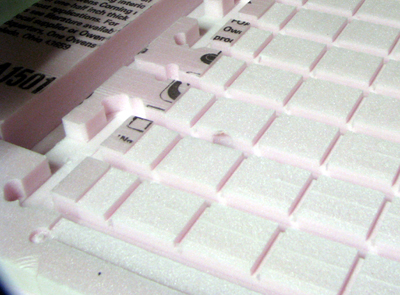

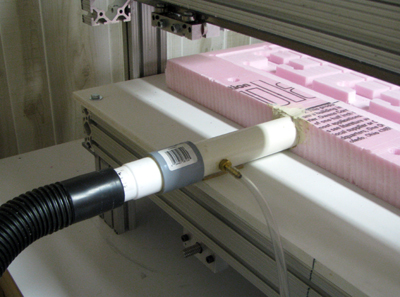

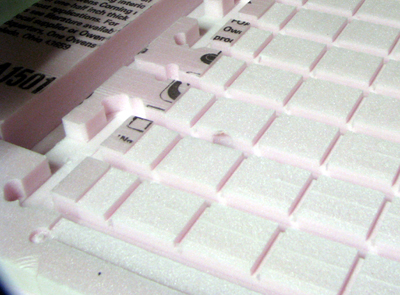

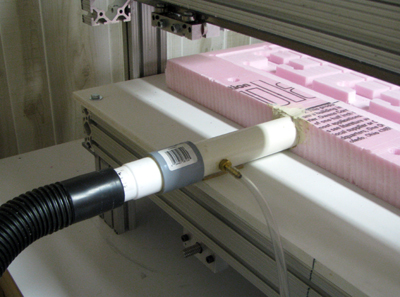

It's cut out of a 2 inch thick piece of styrofoam insulation

board. Not shown in either the pictures or on the drawing is the

full grid of slots for distribution the vacuum. It's 1/8 inch slots on

the odd 1/2 inch channels, 1/4 inch slots on the 1 inch channels and

1/2 inch slots on the 2 inch channels. The vacuum area is a

29x20 inch grid of holes on 1/2 inch centers. These are cut into a 1/8

inch thick piece of fiberboard that is 31x22 inches. I used a 2mm

(.078) pc board drill to make the holes.

I

got very good hold down on larger parts, but I had problems with small

parts (under 2 sqin). That might be attributed to several factors. I

was using a 2 flute end mill. The upcut mills tend to lift the

workpiece. I was using an agressive depth of cut, resulting in more

side force on the workpiece. I was not using tabs on the parts to keep

them in place. At the same time that I was testing out vacuum hold down

I was also having positioning problems on my CNC machine. I have

temporarily abandoned my quest for a vacuum table until the other

problems are fixed and I have more experience cutting parts using

conventional hold down.