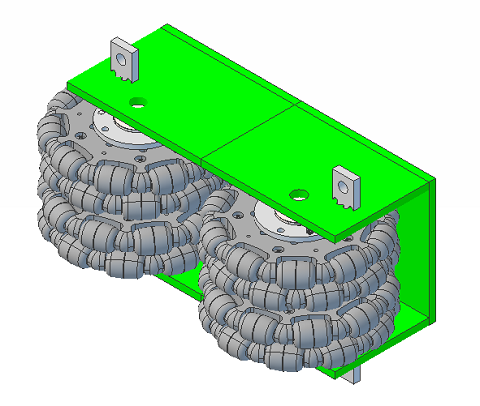

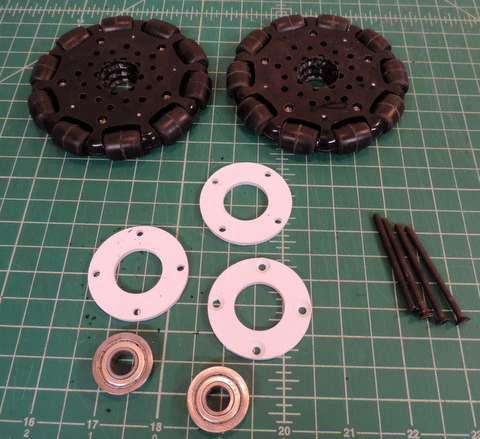

| Left:

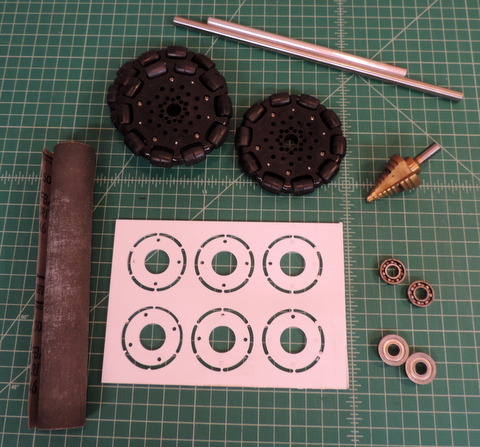

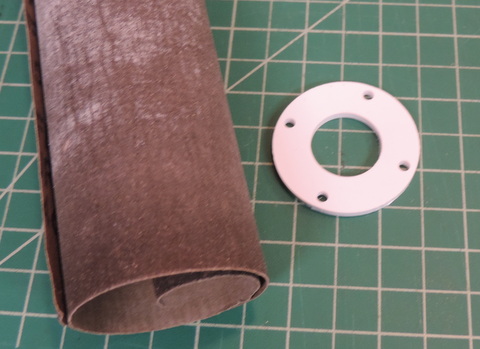

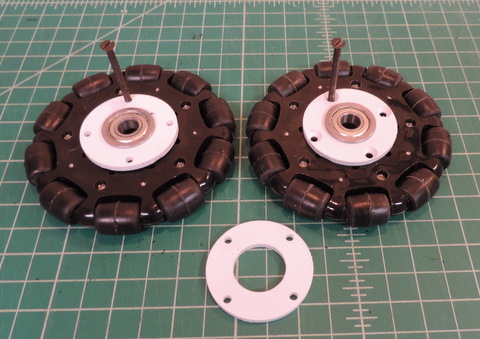

The assortment of parts we're starting with. The CNC panel of

bearing mounts is version 1 and will be updated. (It's parts for only 4

wheels, Version 2 will have twice as many parts.)

Above:

remove the parts from the panel & trim off the tabs. Not shown in

this version, one spacer of each set of 3 will have countersunk holes,

another one will have a recess for the hex nut. The third one is used

as a spacer between the two wheels. |

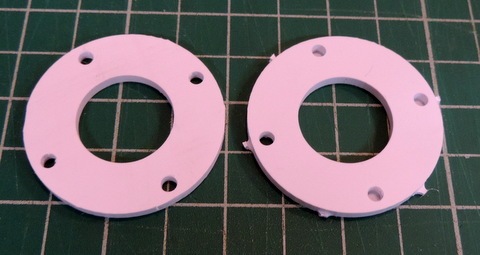

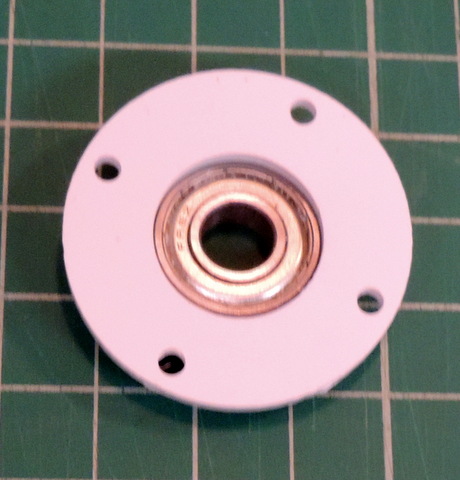

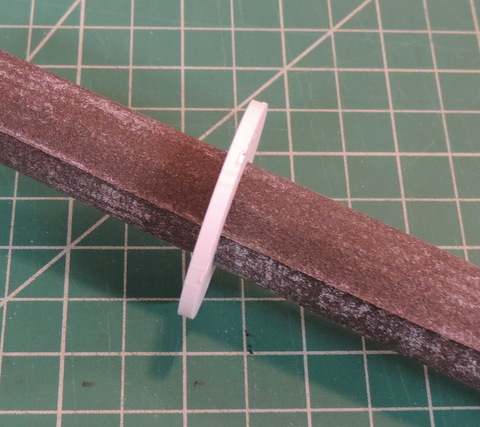

| Left: The bearing , most likely, will not fit in the bearing mount. It's intended to be a tight fit.

Below: To enlarge the hole roll a sheet of fine sandpaper with the grit out.

|

| Left:

Slide the roll into the bearing mount and let it unroll. Then

slide it back and forth a few times - check the fit. It won't take much

sanding. Don't over do it!

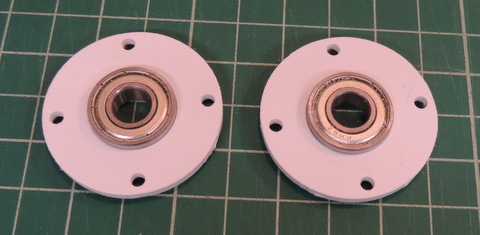

Below: Bearings in the bearing mounts |

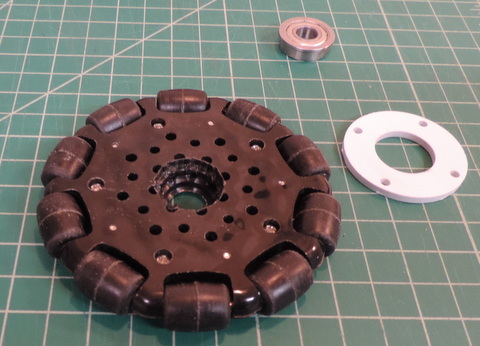

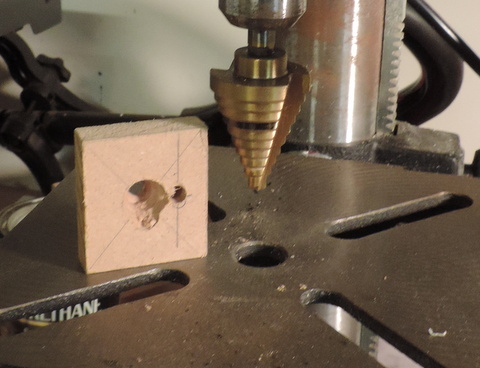

In

order for the bearing to fit you have to enlarge the center bore of the

Servo City Wheels from 1/2 in to 7/8 in. The easiest way to do that is

with a Step Drill. I got mine from Amazon (see parts list ) You only

have to enlarge to a depth of 1/8 inch. I've marked my drill with a

marker so I know where to stop.  |

Wheel after bore is enlarged. |

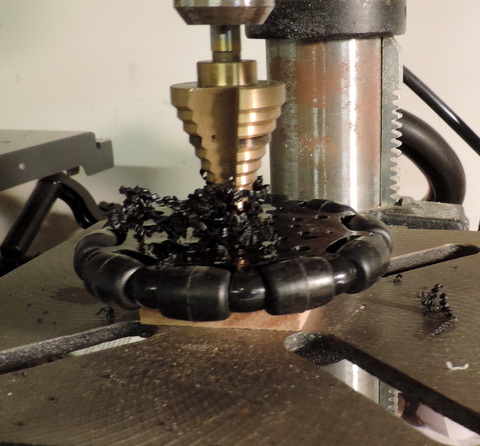

Above:

I put a block of wood under the wheel because the Step Drill extends

through the wheel body. (yes, I've drilled into the table of my drill

press. avoid that if you can - it dulls the drill bits!)

Right:

The swarf will obscure your progress - Turn off the Drill, wait for it

to stop spinning, and clean it off! Then continue... |  |

Bring one of the bearing mounts with you when you are drilling so you can check the depth of the bore. |

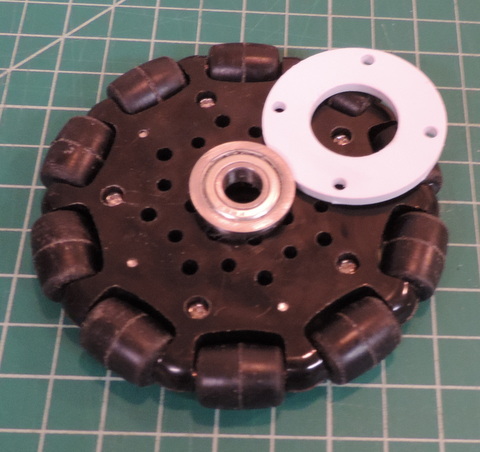

We're

ready to begin assembly. They are hard to see, but I added countersinks

to the holes in one of the mounts. The shop didn't do them in Version 1. |

Use

the screws to align the holes in the bearing mount with the holes in

the wheel. (there are 10 holes in the wheel.). Don't bother doing the

2nd wheel, the bearing mount will pop out while you align the first

wheel with the second one. Note: the screws shown here are actually too

long. You'll have a choice of using 1.5 in screws or 3.0 in screws.

(more later) |

Turn the first wheel over and slide the space (3rd bearing mount) on over the screws. |

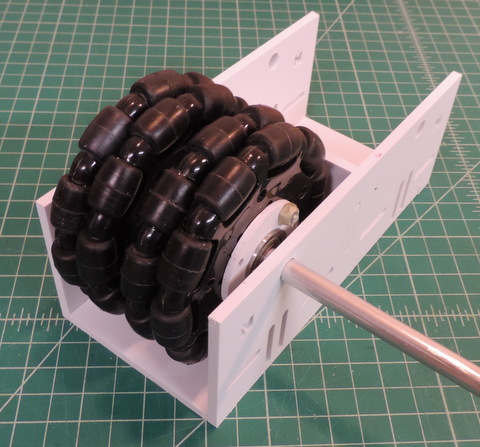

Align the second wheel so that' it's Omni Bearing are centered between the ones of the first wheel. |

Modify

and Assemble a second set of wheels (Actually 3 more sets!) Install on

your axle with the flat head screws in the center. |

More

to come: Version 2 of the Bearing Mount panel will have a set of 3

spacer rings to be used between the two sets of omni wheels and

on either side of the pair of wheels. As mentioned above one bearing

mount will have CNC cut countersinks for the flat head screws, the

other one will have a hex recess for the Nylon Lock Nuts. I'll also be

experimenting with using 3 in screws so you can lock all 4 wheels into

alignment if you want to. For right now we at least have a workable

alternative.

Click Here for the Parts List |