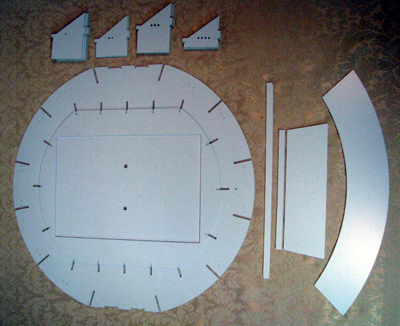

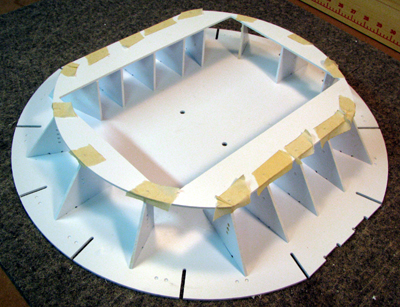

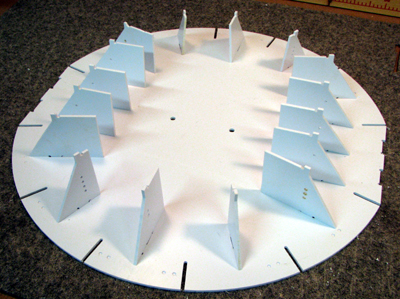

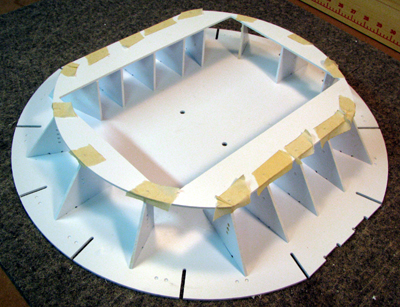

familiarize yourself with the parts. do a trial fit of the risers

into the skirt base (ring 0) |

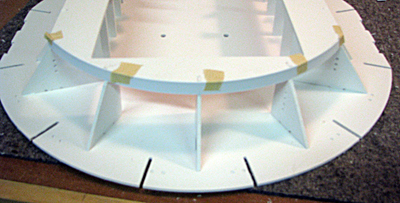

put the skirt bottom in place verify the fit as well |

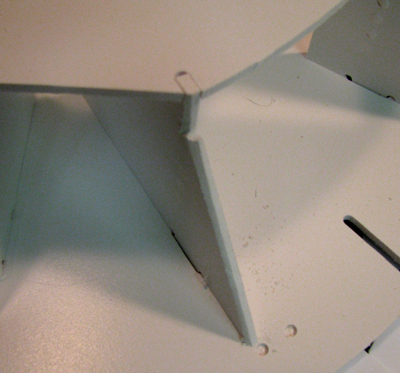

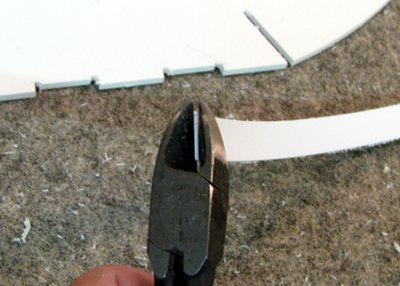

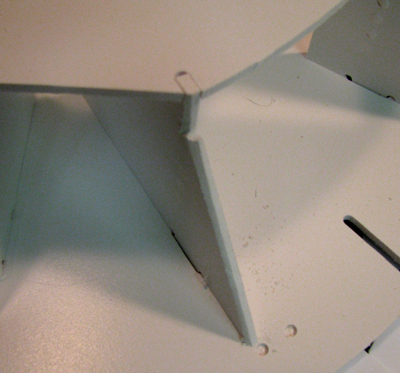

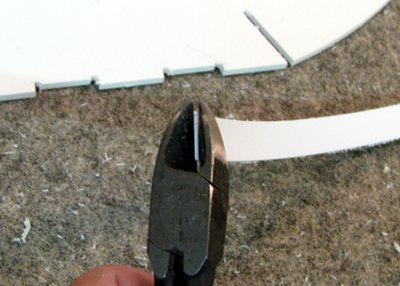

note that riser c has to be chamfered. this can be done

before or after you glue things in place. it's up to you.

right: edges of riser after chamfering. if you want a

stronger bond you can glue pieces of scrap styrene

to the edge of the angled part of the riser. |  |

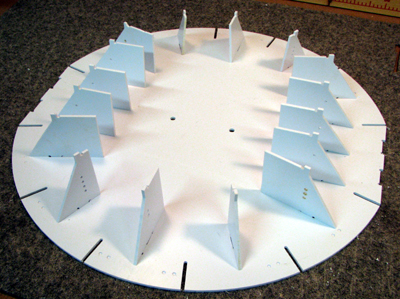

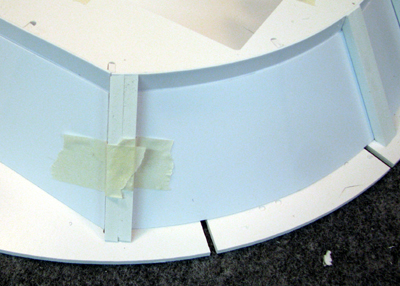

you have a choice depending on how you like to work. tape the

risers so that the edge is flush with the skirt bottom. you can do

it before or after you apply the glue. |

tape all of the risers so they stay in alignment |

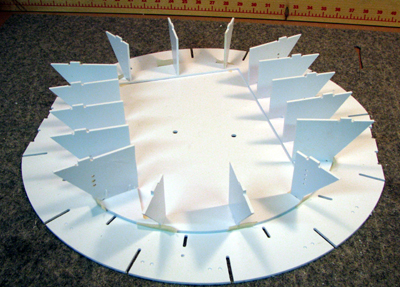

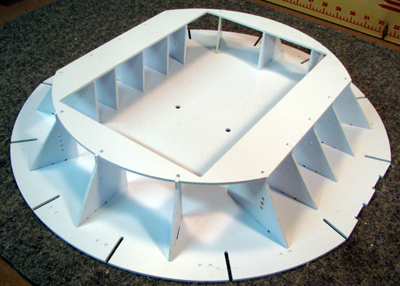

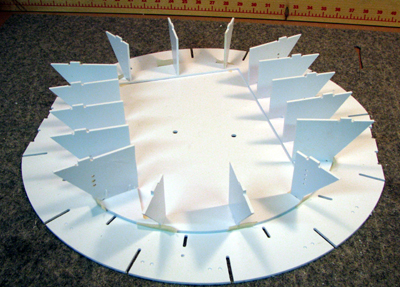

when the glue sets check the alignment. make sure the risers are

square and flush with the edge of the skirt bottom.

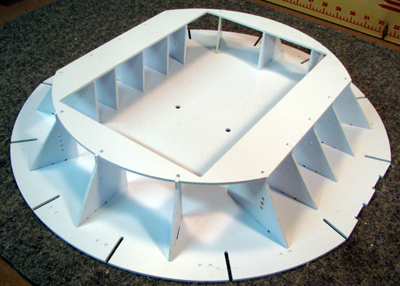

reassemble to the skirt base and glue in place. |

only glue the curved side piece to the 3 center risers.

do not glue to the end risers.

those ends will be glued when you glue the straight

side pieces in place. |

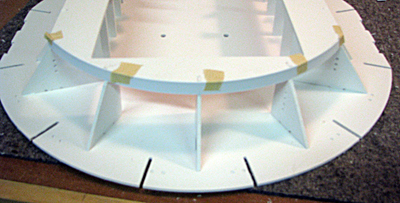

all of the .040 pieces have been left slightly over length so

they can be trimmed to a precise fit. trim the end of the

curved piece and the straight side piece it mates with. |

I find it easy to trim pieces like this with a diagonal cutter. |

glue the straight side piece in place and let the glue set. |

trial fit the cone shaped side. note the pencil mark for the center.

like the straight side piece, only glue to the 3 center ribs. leave the

ends loose to fit and glue with the angled side pieces. |

first trail fit the angled side pieces. trim the ends as needed so

that everything comes together neatly.

right: once you are happy with the fit, glue the angled sides

to the risers and glue the miter joints on the end. |  |