When I designed my R2 Battery Boxes I 3D printed

the curved ends. It takes about 5.5 hours to print one curved end and

they are about 1/2 the height of Chopper's Battery Boxes.

When

I announced my intent to cut Chopper's parts from Extruded Acrylic

tubing, a number of folks warned me that it was difficult to machine.

While I don't disagree, it's both hard and brittle, but I've found it

manageable.

|

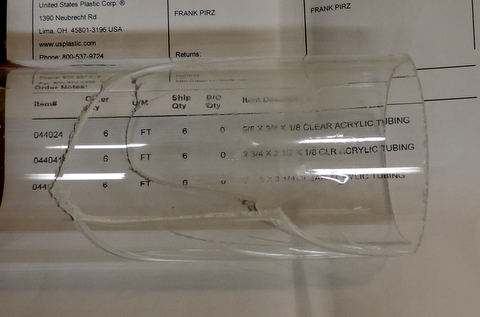

This is what happens when UPS drops the box!

|

To cut the tubing I've extended the table on my chop saw and installed a plastics cutting blade. |

|

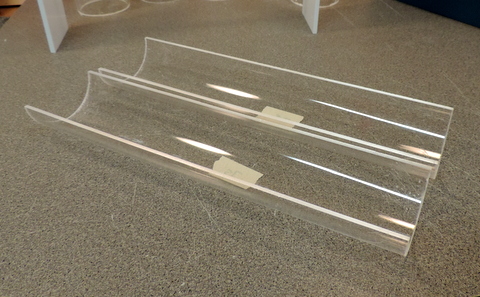

Left: After cleaning up the cut edges I've got a set of tubes to be slit lengthwise

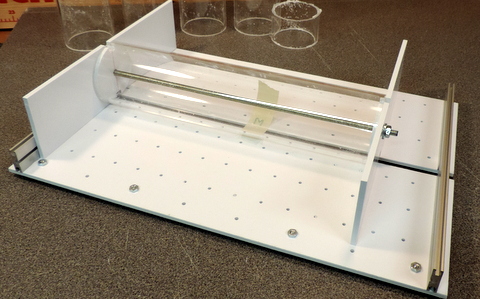

To

do the Slitting the tube is mounted into a fixture and then clamped

onto a sled. The fixture insures that when I turn the tube over the

second cut will line up with the first one. The sled keeps my

fingers away from the router bit! |

I've removed the rear guide from a this router bench and I'm using the guide channel in the front edge to line up the sled. |

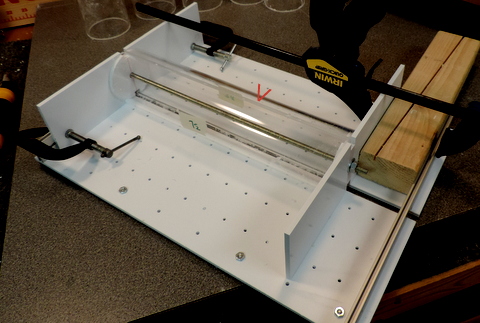

This

is the tube after turning over and making the second cut. It's hard to

see but there's a cut line where the V is pointing to above. |

| Left: A pair of Half tubes ready to go into a Battery Box.

I'm using the same approach, with a modified fixture, to cut the curved 'trench' that I'm using in Chopper's Foot Drive. |