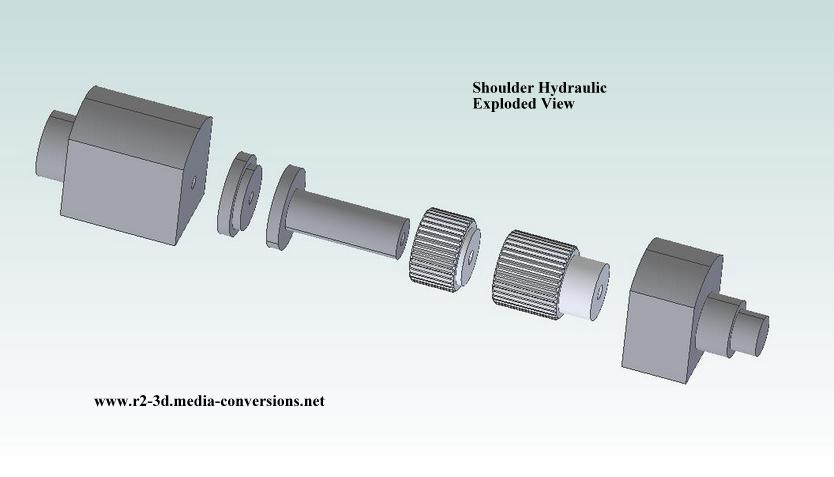

The Printed Parts

Parts aligned by styrene rod & clamped for gluing

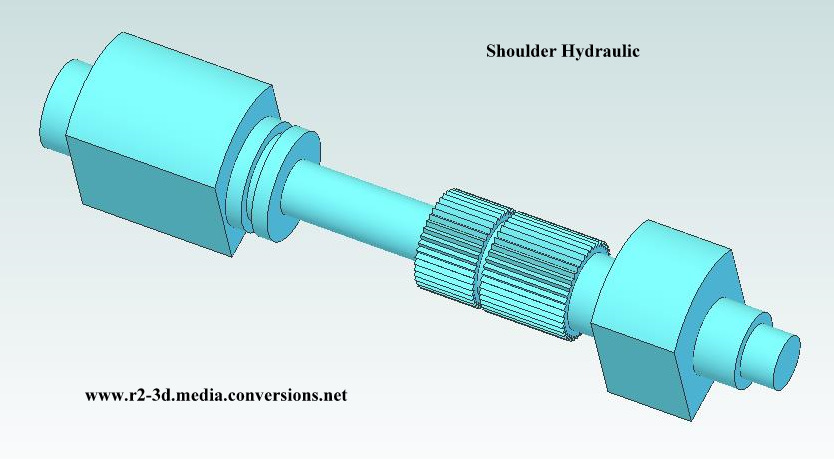

Shoulder Hydraulics are sold in pairs - see the Part List

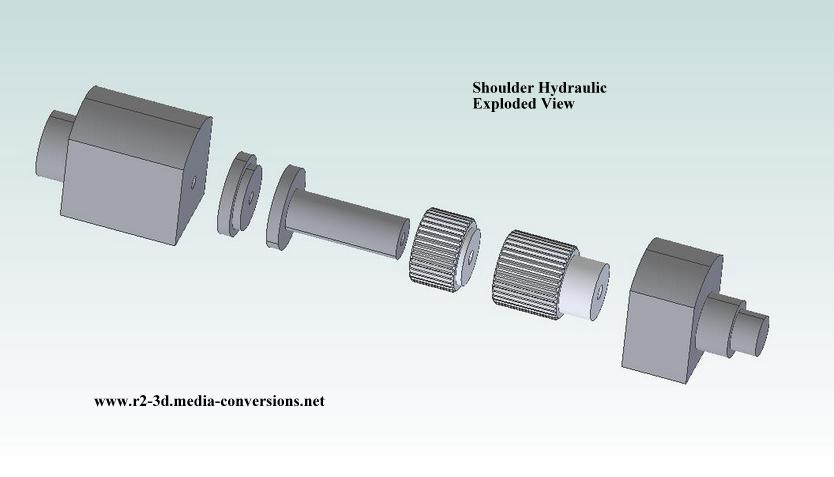

Image kindly provided by R2 Builder David Codding

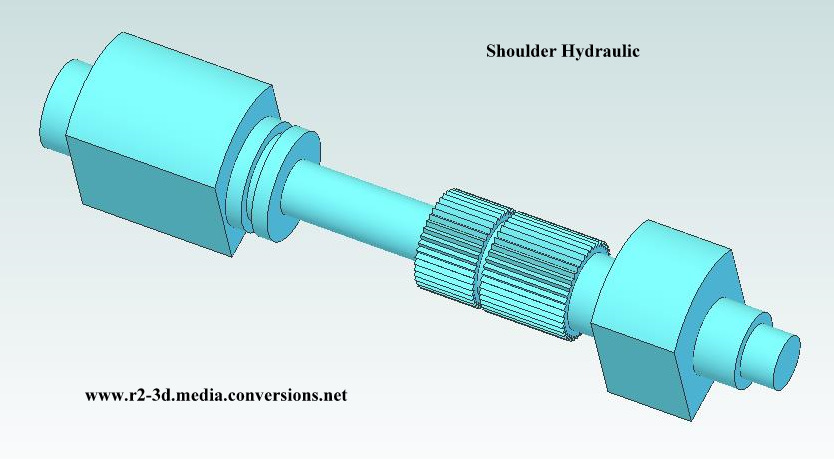

Shoulder Hydraulics

| 3D Printed Shoulder Hydraulics | |

|

|

| |

The Printed Parts | |

Parts aligned by styrene rod & clamped for gluing | |

| Shoulder Hydraulics are only only sold as a finished assembly Shoulder Hydraulics are sold in pairs - see the Part List | |

| 3D Finished Parts Installed in Shoulder Horseshoe | |

Image kindly provided by R2 Builder David Codding |

| Home |