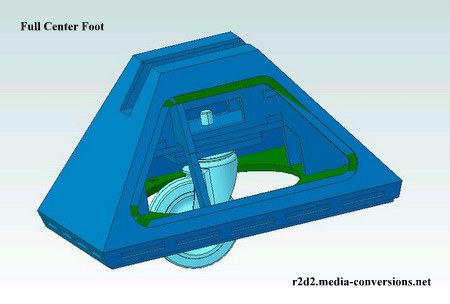

The image links to a 3d pdf file, click on it if you want to be able to rotate the image around and examine it from other angles. (Note, the 3d.pdf file opens in a new window. If you have problems with the 3d feature you may have to upgrade to the latest version of Adobe Reader).

After 'activating' the 3d mode by clicking on the display

select a part by left clicking on it (the part will be highlighted)

then right clicking brings up a window. Follow the sequence

-> part options -> part render mode -> transparent

to make the outer parts transparent and the inner

details visible.

Or you can use the views below which also link to .pdf files.

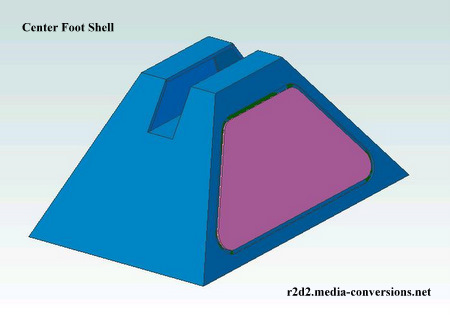

The image, like the one above, links to a 3d pdf file.

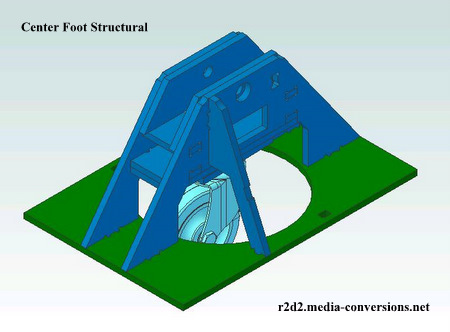

The image, like the one above, links to a 3d pdf file.