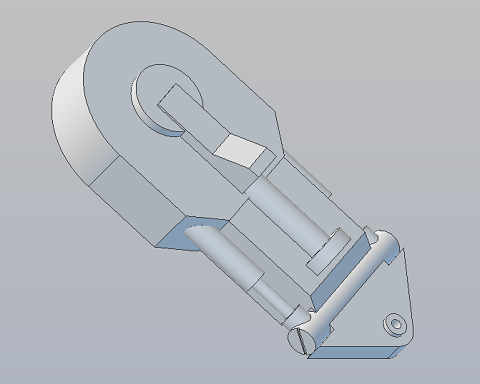

The

remaining (older) drawings show the internal structure.

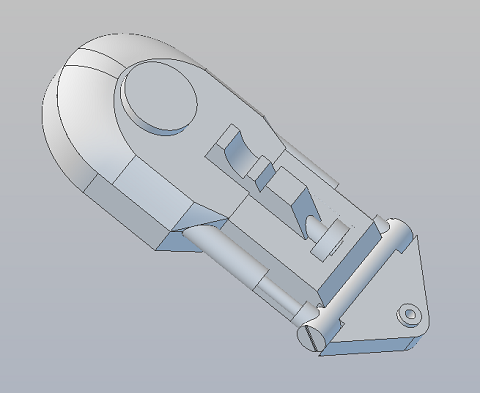

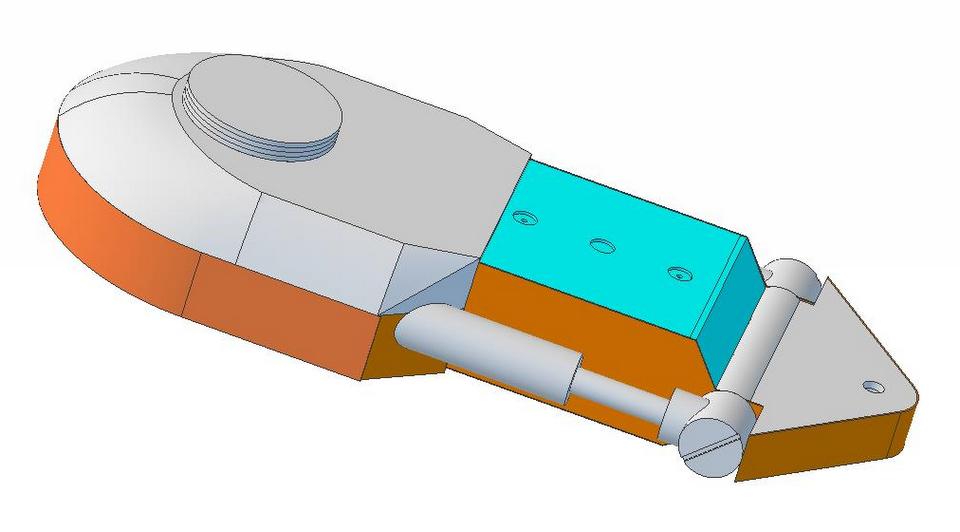

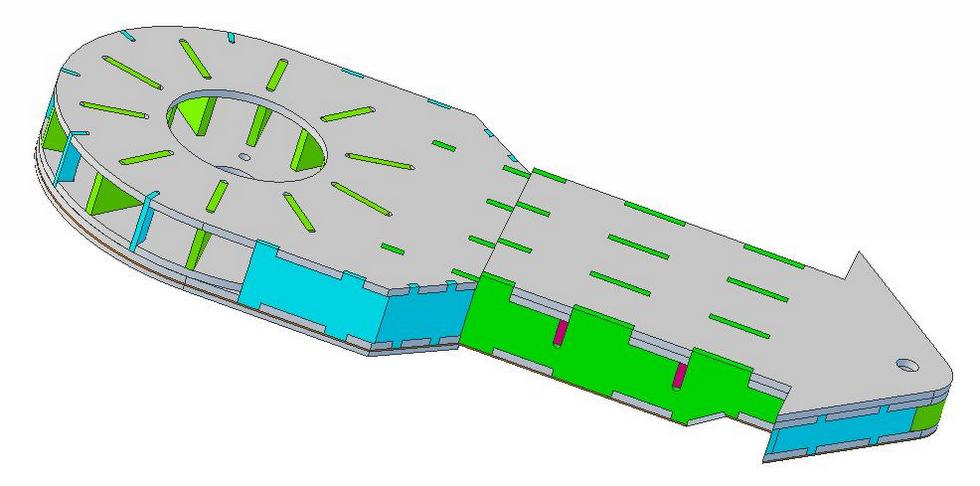

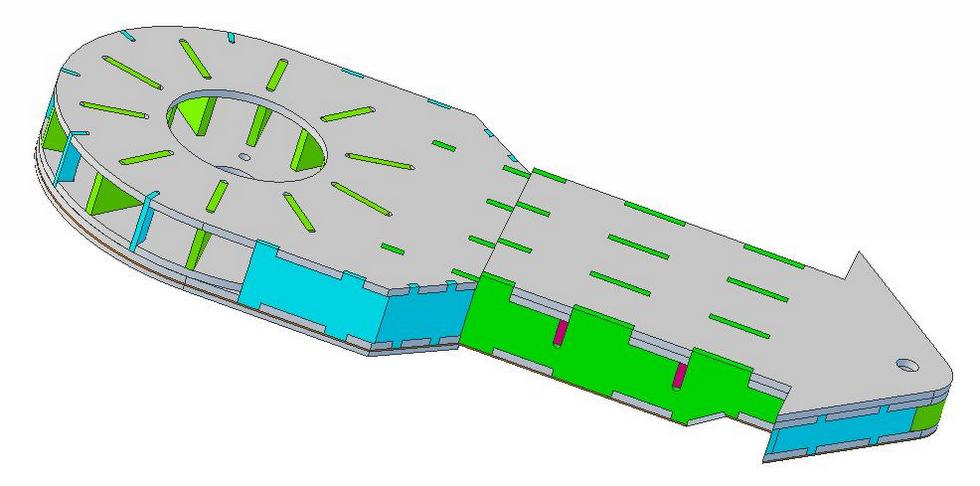

Leg

Frame design is a structural component common to both legs. In this

image it's wrapped with .040 skins (2 layers on the curved top portion).

|

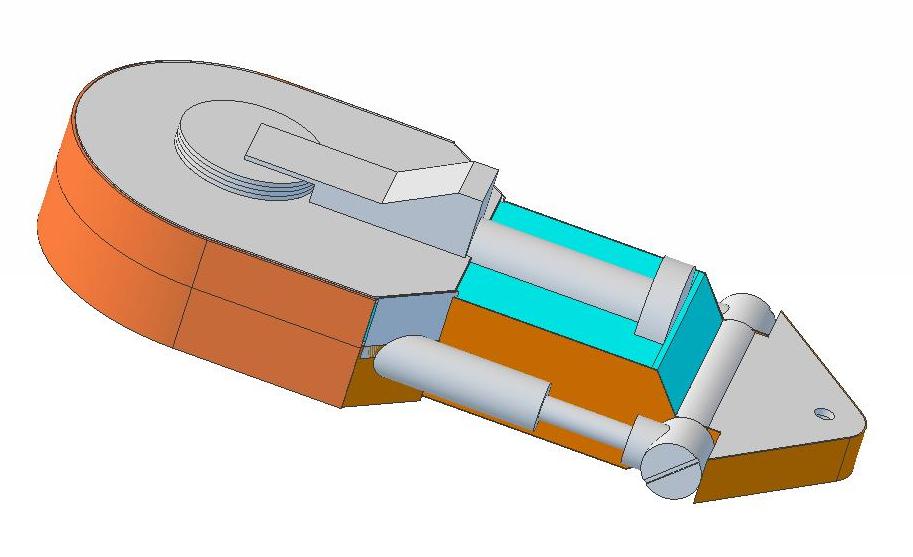

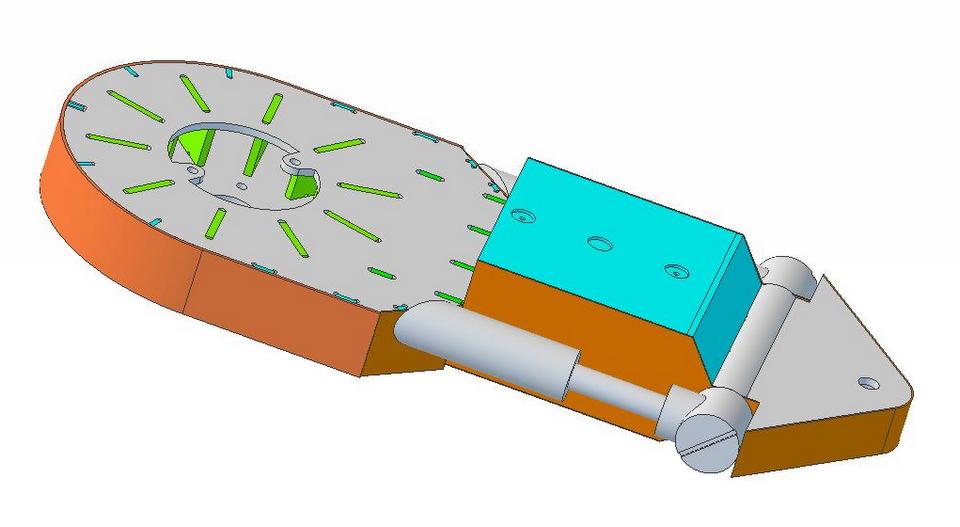

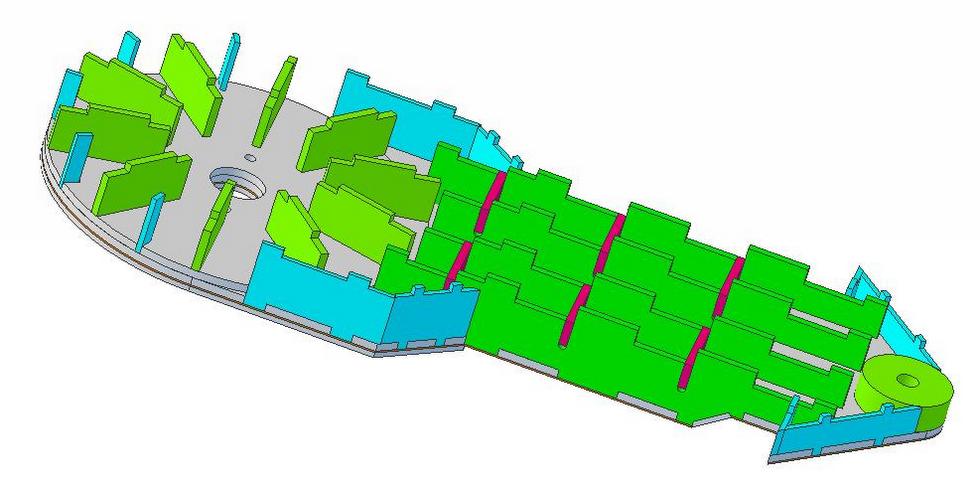

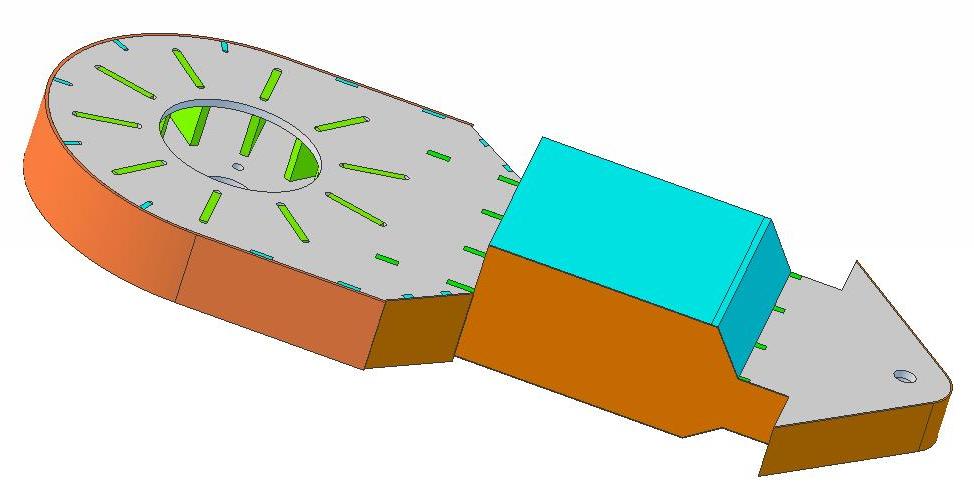

Here we have peeled off the .040 skins. The blue color

components are .125 thick non-structural parts of the design. The

balance of the parts are all .1875

|

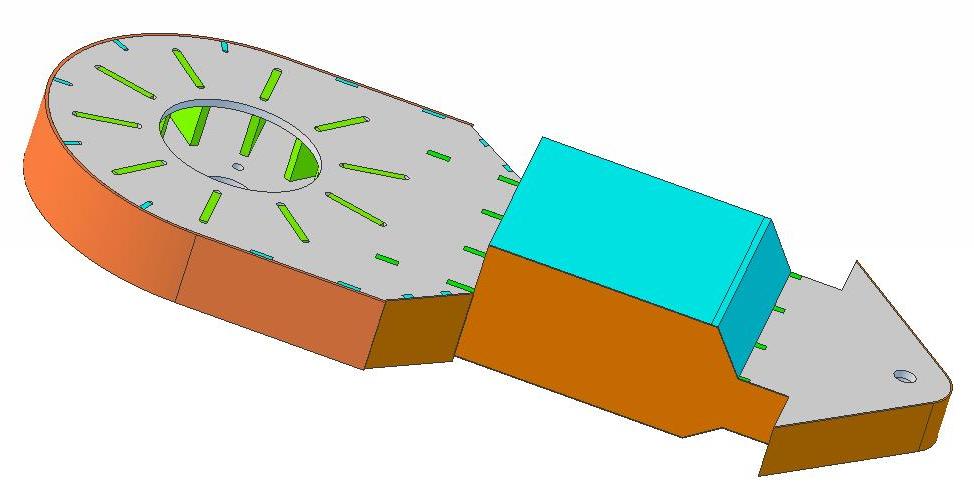

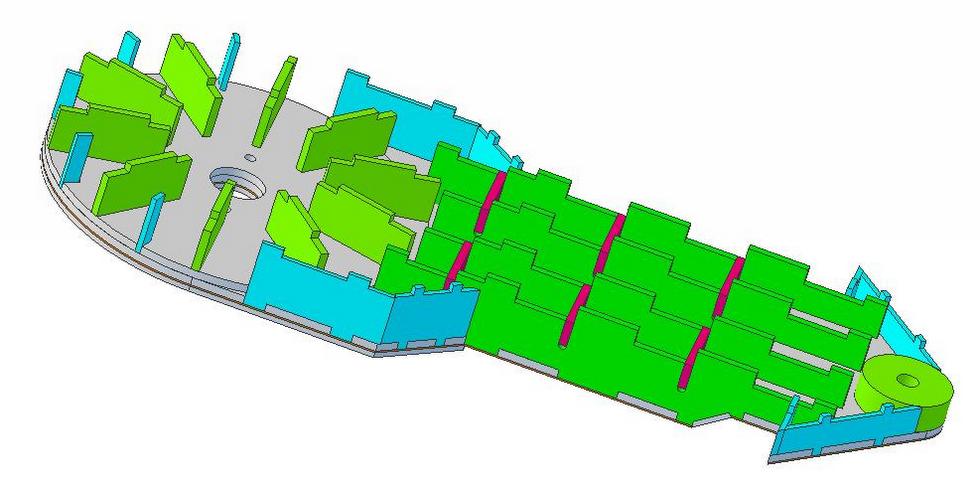

For

strength, the leg has 3 layers of .1875 styrene, with an additional

layer in the area where the leg bolts to the body. As a result of the

change in thickness of the leg where it is mounted to the foot, there

are 2 layers in the top inner section and 2 layers in the bottom outer

section of the leg.

|

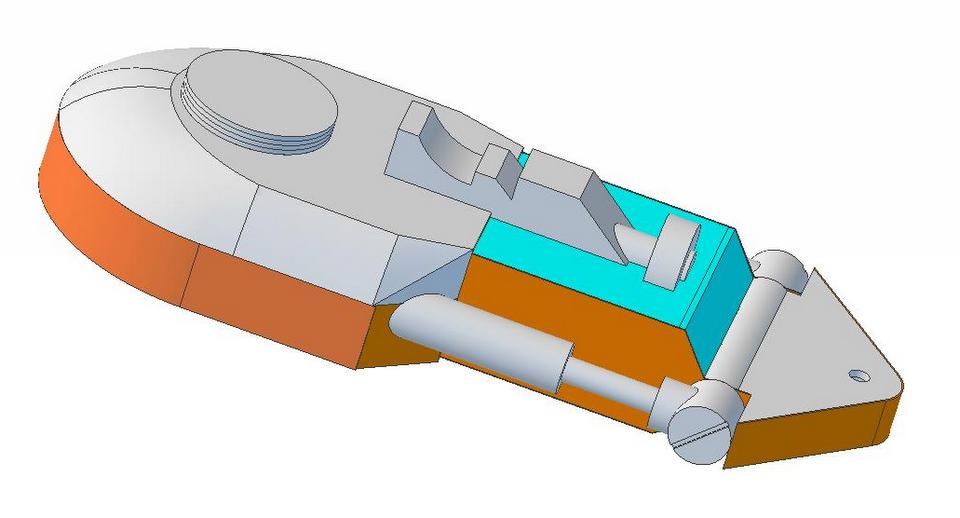

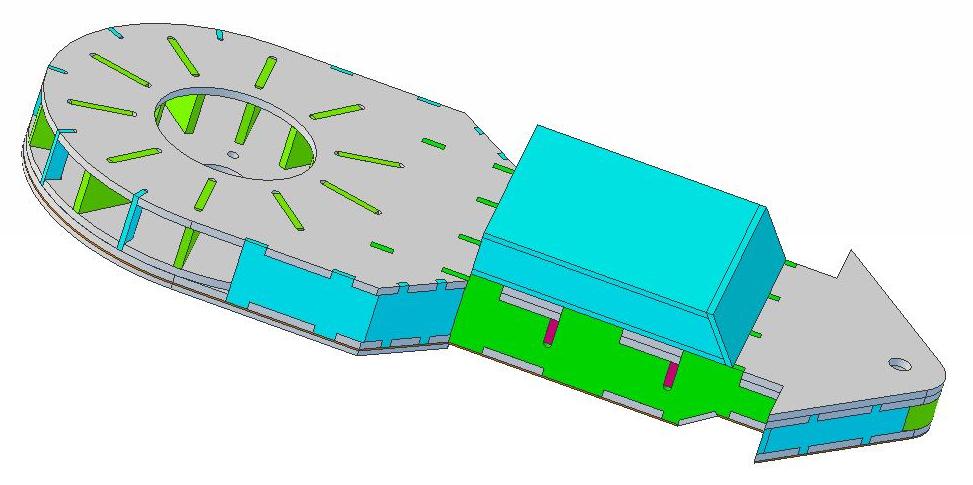

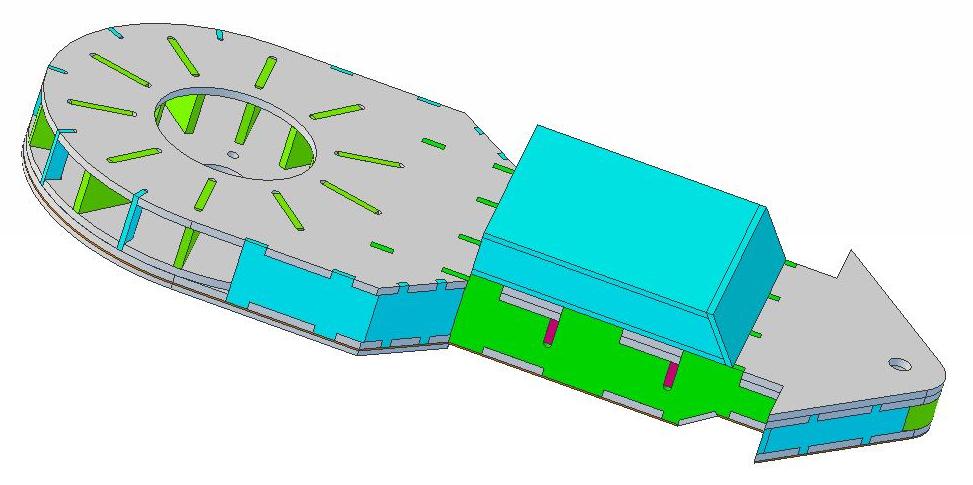

With the outer layer peeled off you can see the box

beam ribs that run top to bottom as well as ribs that radiate around the area

where the leg bolts to the body. The center channel between the

shoulder and the foot is unobstructed for wiring between the body and

the foot. Not shown is the hole at the bottom of

the legs for the wires to exit. It's location is dependent on which

side of the body the leg is built for. |

What's still to be done: It's my first pass at

designing parts to be cast. More than likely I've done some things that

will make casting the parts more difficult. I'm waiting to get feedback

on the parts I'm proposing to have made,

Design 'cleanup' - the bevel edges on most of the parts that have

them are cut to the angles dictated by the design. Bevel cutters are

restricted to the available set of 15,30,45 degree angles. The bevels

will be modified so that the edges meet where needed.

Please ask

questions, make comments & suggestions that you think

might improve the design.

Contact me using: fpirz (at)

media (dash) conversions

(dot) net |